40 years of composite engineering innovation stands behind the durable and customizable underground fiberglass tanks from Xerxes by Shawcor.

Call or email us today to discuss how we can help with Water and Wastewater Storage Solutions.

Onsite Wastewater Tanks

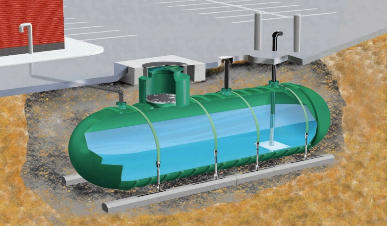

Built to be reliable and highly efficient, our fiberglass tanks offer customers watertight, corrosion-resistant storage for their systems. Xerxes wastewater tanks are ideal for private residence installations, as well as community, municipal, industrial and commercial applications. Our tanks can be designed and configured to meet a range of flows, capacities and site requirements.

Stormwater Tanks

Watertight fiberglass underground tanks can be used to harvest and reuse stormwater to irrigate parks, gardens and recreational fields. These applications help reduce water consumption and provide sustainable benefits for communities.

Fiberglass is uniquely corrosion resistant, resulting in a longer material lifecycle.

Water Conservation Tanks

Xerxes fiberglass water storage tanks provide maximum reliability and watertight performance, making them ideal for rainwater harvesting, stormwater retention and detention, chiller-unit condensation collection and greywater collection. Facility designers often specify fiberglass tanks for collection and reuse systems, which qualify for LEED® green building points.

Municipal Wastewater

Our fiberglass underground storage systems are engineered pipe and tank design modules. They’re easily installed and self-cleaning, reducing maintenance, odors and solids buildup – especially compared to other, flat-bottomed collection systems. Fiberglass is corrosion resistant compared to concrete, providing a longer lifecycle to the system.

Fire Protection Tanks

System designers and installers know that the best standby sources of water for fire protection needs are stored in an underground or aboveground fiberglass tank. Our watertight tanks are the reliable, long-term solution for safely storing water – and protecting it from freezing conditions – whether the location is inside a facility or in a nearby underground site. Xerxes has a proven track record of designing and manufacturing watertight tanks, with hundreds of thousands of long-term installations throughout North America.

Potable Water Storage Tanks

Engineers design water distribution and handling systems with Xerxes potable water storage tanks, because they are manufactured with NSF 61-listed materials at our NSF 61-certified manufacturing facilities. This gives customers the assurance they need when installing storage tanks for public water systems. Xerxes quality assurance measures and facility inspections help to ensure our tanks continue to deliver reliable, high-quality performance.

Grease Interceptors

Foods-service establishments, such as C-stores and fast-food outlets, are increasingly required to install grease interceptors to collect corrosive fats, oils and grease (FOG) before the waste enters wastewater systems.

Xerxes interceptors are designed to meet or exceed municipal FOG discharge regulations.

Oil Interceptors

Business owners install oil separators to prevent environmental pollution and avoid costly fines.

Our oil interceptors are designed for maximum performance in capturing and storing harmful liquids and solids, including hydrocarbon oils. We make our interceptors from durable, non-corrosive fiberglass to keep the environment safe. The smooth, cylindrical shape of our tanks allows for easier cleaning and removal of oil and sediment sludge.

Oil-Water Separators

Xerxes oil-water separators offer high-efficiency, long-lasting solutions for managing water and effluent runoff from parking lots or equipment washdown stations.

Tank designers can select the appropriate flow rate and spill capacity for their specific needs, making Xerxes tanks an ideal long-term solution for a variety of sites and applications, including vehicle repair garages, bulk fuel plants, truck stops and other industrial and commercial sites.

Industrial Wastewater Tanks

Our corrosion-resistant fiberglass tanks are ideal for factory washdown, emergency spills and landfill leachate runoff. Double-wall tanks with interstitial monitoring systems securely capture hazardous materials before they are either removed from the site or treated to neutralize them.

We also manufacture tanks to collect chemically contaminated fire-protection water and aqueous film-forming foam (AFFF) runoff.

Water Tank Accessories

From complex site configurations to custom designs, Xerxes’ wide selection of turnkey tank accessories and fittings will pair perfectly with your project and site requirements. Avoid costly, time-consuming third-party ordering, let our experienced customer service, sales and engineering support teams provide you with the right solution for your project.

Tank Installation Procedure Videos

We provide detailed contractor training, installation manuals, procedure instructions, step-by-step videos, and support documentation to help ensure tanks are installed correctly. Contact us for more information.

Click here to see the Xerxes Installation Manual and Operating Guidelines.

Wastewater, Potable Water, and Fire-Protection Tanks for Breweries, Wineries, and Distilleries

Many breweries, wineries, and distilleries want to go beyond collecting wastewater and/or rainwater. They know that the best environmental solution is to also treat and reuse their wastewater. Besides safely storing wastewater, tanks also can be configured to treat wastewater that can be turned into ultrafiltered water for: vineyard irrigation, landscape watering, water features and dust control.

Such facilities often need potable and fire-protection tanks as well. Our potable water tanks can be manufactured to meet NSF 61 requirements. Some wineries, for instance, have NSF 61 labeled tanks for potable water, with the added benefit of being used for emergency fire protection water.

A Xerxes tank can be customized and scaled to meet the needs of such facilities of any size.

Wastewater / Decontamination and Fire-Protection Tanks for Hospitals

There is a rapidly growing awareness for the need to remove or neutralize contaminants from personnel, clothing and textiles, equipment and tools, vehicles, floors and other surfaces. Both medical facilities and wastewater systems need to be prepared for the presence of chemical and biological substances.

A Xerxes fiberglass decontamination tank has all the benefits of a structurally strong, corrosion-resistant fiberglass tank. Plus, our double-wall tanks meet relevant regulatory requirements and greatly reduce the risk of expensive leak-related cleanups and maintenance.

Our decontamination tanks are designed to meet a variety of applications and site requirements.

Designed to withstand AASHTO’s H-25/HS-25 axle loads

Minimum Depth of Cover for areas without traffic:

12” backfill

Minimum Depth of Cover for areas with traffic:

36” (91 cm) backfill

18” (46 cm) backfill + 6” (15 cm) reinforced concrete

18” (46 cm) backfill + 8” (20 cm) asphalt pavement

Maximum burial depth for standard tanks is 7 feet of cover the top of the tank.

The information above is for Tanks other than Petroleum Tanks, per Table 7-1 of the attached Xerxes Installation Manual and Operating Guidelines.